US8846021B2 - Acryloyloxyethylphosphorylcholine containing polymer conjugates and their preparation - Google Patents

Acryloyloxyethylphosphorylcholine containing polymer conjugates and their preparation Download PDFInfo

- Publication number

- US8846021B2 US8846021B2 US13/959,563 US201313959563A US8846021B2 US 8846021 B2 US8846021 B2 US 8846021B2 US 201313959563 A US201313959563 A US 201313959563A US 8846021 B2 US8846021 B2 US 8846021B2

- Authority

- US

- United States

- Prior art keywords

- alkyl

- group

- compounds

- biologically active

- polymer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 0 *CC(C)(C)C(=O)O[3H] Chemical compound *CC(C)(C)C(=O)O[3H] 0.000 description 60

- VYHCMIQWQKWTCB-UHFFFAOYSA-L C.C.C.C.CCCOP(=O)([O-])OCCOC(=O)C(C)(Br)CC(C)(C)C(=O)OC1=CC(C=O)=CC(OC(=O)C(C)(C)CC(C)(Br)C(=O)OCCOP(=O)([O-])OCCC)=C1 Chemical compound C.C.C.C.CCCOP(=O)([O-])OCCOC(=O)C(C)(Br)CC(C)(C)C(=O)OC1=CC(C=O)=CC(OC(=O)C(C)(C)CC(C)(Br)C(=O)OCCOP(=O)([O-])OCCC)=C1 VYHCMIQWQKWTCB-UHFFFAOYSA-L 0.000 description 1

- ZSZRUEAFVQITHH-UHFFFAOYSA-N C=C(C)C(=O)OCCOP(=O)([O-])OCC[N+](C)(C)C Chemical compound C=C(C)C(=O)OCCOP(=O)([O-])OCC[N+](C)(C)C ZSZRUEAFVQITHH-UHFFFAOYSA-N 0.000 description 1

- YIHBOFFJLUVDQS-UHFFFAOYSA-N C=C1C=C(SC(C)C)C(=O)N1.CCC Chemical compound C=C1C=C(SC(C)C)C(=O)N1.CCC YIHBOFFJLUVDQS-UHFFFAOYSA-N 0.000 description 1

- IMZBZJQZTZXTQI-UHFFFAOYSA-N C=C1C=CC(=O)N1 Chemical compound C=C1C=CC(=O)N1 IMZBZJQZTZXTQI-UHFFFAOYSA-N 0.000 description 1

- WAVDUEACJAUMLX-UHFFFAOYSA-N CBr.CCC.CCC.CCC.CCCC Chemical compound CBr.CCC.CCC.CCC.CCCC WAVDUEACJAUMLX-UHFFFAOYSA-N 0.000 description 1

- QBJWGGWPQPRVKW-UHFFFAOYSA-N CC(C)(Br)C(=O)ON1C(=O)CCC1=O Chemical compound CC(C)(Br)C(=O)ON1C(=O)CCC1=O QBJWGGWPQPRVKW-UHFFFAOYSA-N 0.000 description 1

- ATOJEKBXBDAOPK-UHFFFAOYSA-N CC(C)(CC(C)(Br)C(=O)OCCOP(=O)([O-])OCC[N+](C)(C)C)C(=O)ON1C(=O)CCC1=O Chemical compound CC(C)(CC(C)(Br)C(=O)OCCOP(=O)([O-])OCC[N+](C)(C)C)C(=O)ON1C(=O)CCC1=O ATOJEKBXBDAOPK-UHFFFAOYSA-N 0.000 description 1

- SEEYREPSKCQBBF-UHFFFAOYSA-N CN1C(=O)C=CC1=O Chemical compound CN1C(=O)C=CC1=O SEEYREPSKCQBBF-UHFFFAOYSA-N 0.000 description 1

- KTGLOAHYGZRPJI-UHFFFAOYSA-N COC(COCCO)OC Chemical compound COC(COCCO)OC KTGLOAHYGZRPJI-UHFFFAOYSA-N 0.000 description 1

- OAXHGDUWLZBMCE-UHFFFAOYSA-N COC(COCCOC(=O)C(C)(C)Br)OC Chemical compound COC(COCCOC(=O)C(C)(C)Br)OC OAXHGDUWLZBMCE-UHFFFAOYSA-N 0.000 description 1

- QTKQTSRNMPNGDL-UHFFFAOYSA-N COC(COCCOC(=O)C(C)(C)CC(C)(Br)C(=O)OCCOP(=O)([O-])OCC[N+](C)(C)C)OC Chemical compound COC(COCCOC(=O)C(C)(C)CC(C)(Br)C(=O)OCCOP(=O)([O-])OCC[N+](C)(C)C)OC QTKQTSRNMPNGDL-UHFFFAOYSA-N 0.000 description 1

- CERQOIWHTDAKMF-MNYXATJNSA-N [3H]OC(=O)C(=C)C Chemical compound [3H]OC(=O)C(=C)C CERQOIWHTDAKMF-MNYXATJNSA-N 0.000 description 1

- VUAXHMVRKOTJKP-MNYXATJNSA-N [3H]OC(=O)C(C)(C)CC Chemical compound [3H]OC(=O)C(C)(C)CC VUAXHMVRKOTJKP-MNYXATJNSA-N 0.000 description 1

- KACIFAFFHHKUKV-UHFFFAOYSA-N [H]C(=O)C1=CC(OC(=O)C(C)(C)Br)=CC(OC(=O)C(C)(C)Br)=C1 Chemical compound [H]C(=O)C1=CC(OC(=O)C(C)(C)Br)=CC(OC(=O)C(C)(C)Br)=C1 KACIFAFFHHKUKV-UHFFFAOYSA-N 0.000 description 1

- NAYSBVGBBMEZJB-UHFFFAOYSA-N [H]C(=O)C1=CC=C(OC(=O)C(C)(C)Br)C=C1 Chemical compound [H]C(=O)C1=CC=C(OC(=O)C(C)(C)Br)C=C1 NAYSBVGBBMEZJB-UHFFFAOYSA-N 0.000 description 1

- JRBAWZIUILFCEW-UHFFFAOYSA-N [H]C(=O)C1=CC=C(OC(=O)C(C)(C)CC(C)(Br)C(=O)OCCOP(=O)([O-])OCC[N+](C)(C)C)C=C1 Chemical compound [H]C(=O)C1=CC=C(OC(=O)C(C)(C)CC(C)(Br)C(=O)OCCOP(=O)([O-])OCC[N+](C)(C)C)C=C1 JRBAWZIUILFCEW-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- A61K47/48176—

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/50—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates

- A61K47/51—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent

- A61K47/56—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent the modifying agent being an organic macromolecular compound, e.g. an oligomeric, polymeric or dendrimeric molecule

- A61K47/58—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent the modifying agent being an organic macromolecular compound, e.g. an oligomeric, polymeric or dendrimeric molecule obtained by reactions only involving carbon-to-carbon unsaturated bonds, e.g. poly[meth]acrylate, polyacrylamide, polystyrene, polyvinylpyrrolidone, polyvinylalcohol or polystyrene sulfonic acid resin

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P1/00—Drugs for disorders of the alimentary tract or the digestive system

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P25/00—Drugs for disorders of the nervous system

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P35/00—Antineoplastic agents

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P5/00—Drugs for disorders of the endocrine system

- A61P5/06—Drugs for disorders of the endocrine system of the anterior pituitary hormones, e.g. TSH, ACTH, FSH, LH, PRL, GH

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P7/00—Drugs for disorders of the blood or the extracellular fluid

- A61P7/06—Antianaemics

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F293/00—Macromolecular compounds obtained by polymerisation on to a macromolecule having groups capable of inducing the formation of new polymer chains bound exclusively at one or both ends of the starting macromolecule

- C08F293/005—Macromolecular compounds obtained by polymerisation on to a macromolecule having groups capable of inducing the formation of new polymer chains bound exclusively at one or both ends of the starting macromolecule using free radical "living" or "controlled" polymerisation, e.g. using a complexing agent

Definitions

- the present invention relates to polymeric reagents and conjugates thereof, methods for synthesizing the polymeric reagents and conjugates, pharmaceutical compositions comprising the conjugates and methods of using the polymer conjugates including therapeutic methods where conjugates are administered to patients.

- Efforts to formulate biologically active agents for delivery must deal with a variety of variables including the route of administration, the biological stability of the active agent and the solubility of the active agents in physiologically compatible media. Choices made in formulating biologically active agents and the selected routes of administration can affect the bioavailability of the active agents. For example, the choice of parenteral administration into the systemic circulation for biologically active proteins and polypeptides avoids the proteolytic environment found in the gastrointestinal tract. However, even where direct administration, such as by injection, of biologically active agents is possible, formulations may be unsatisfactory for a variety of reasons including the generation of an immune response to the administered agent and responses to any excipients including burning and stinging. Even if the active agent is not immunogenic and satisfactory excipients can be employed, biologically active agents can have a limited solubility and short biological half-life that can require repeated administration or continuous infusion, which can be painful and/or inconvenient.

- bioactive agents For some biologically active agents a degree of success has been achieved in developing suitable formulations of bioactive agents by conjugating the agents to water soluble polymers.

- the conjugation of biologically active agents to water soluble polymers is generally viewed as providing a variety of benefits for the delivery of biologically active agents, and in particular, proteins and peptides.

- PEG polyethylene glycol

- a reduction in immunogenicity or antigenicity, increased half-life, increased solubility, decreased clearance by the kidney and decreased enzymatic degradation have been attributed to conjugates of a variety of water soluble polymers and bioactive agents, including PEG conjugates.

- the polymer conjugates of biologically active agent require less frequent dosing and may permit the use of less of the active agent to achieve a therapeutic endpoint. Less frequent dosing reduces the overall number of injections, which can be painful and which require inconvenient visits to healthcare professionals.

- PEGylation of biologically active agents, remains a challenge as PEG conjugation may result in the loss of biological activity.

- a variety of theories have been advanced to account for loss of biological activity upon conjugation with PEG. These include blockage of necessary sites for the agent to interact with other biological components, either by the conjugation linkage or by the agent being buried within the PEG conjugate, particularly where the polymer is long and may “wrap” itself around some or the active agent, thereby blocking access to potential ligands required for activity.

- Branched forms of PEG for use in conjugate preparation have been introduced to alleviate some of the difficulties encountered with the use of long straight PEG polymer chains. While branched polymer may overcome some of the problems associated with conjugates formed with long linear PEG polymers, neither branched nor linear PEG polymer conjugates completely resolve the issues associated with the use of conjugated bioactive agents. Both linear and branched PEG conjugates can, for example, suffer from rates of degradation that are either too long or too short. A rapid rate of degradation can result in a conjugate having too short of an in vivo half-life, whereas, too slow of a rate of degradation can result in an unacceptable long conjugate half-life in vivo.

- the present invention relates to polymeric reagents and conjugates thereof, methods for synthesizing the polymeric reagents and conjugates, pharmaceutical compositions comprising the conjugates and methods of using the polymer conjugates including therapeutic methods where conjugates are administered to patients.

- the invention provides compounds of formula (Ia) or a salt, hydrate, or solvate thereof: (X-(Sp 1 ) n ) a -L-(K) b (Ia) where

- Another group of embodiments is directed to compounds of formula (IIa), which are embodiments of compounds of formula (Ia) where a and b are both 1,

- Another group of embodiments is directed to compounds of formulas (Ia) (IIa), (IIIa) (IVa) and (Va) where:

- Another group of embodiments relates to compound comprising a biologically active agent bonded to a phosphorylcholine containing polymer.

- Another group of embodiments relates to compound of formula (Ib) or a salt, hydrate, or isomer thereof: (A-Z-(Sp 1 ) n ) a -L-(K) b (Ib) where

- Another group of embodiments is directed to compounds of formulas (Ib) (IIb), (IIIb) (IVb) and (Vb),

- the biologically active agent, A may include a spacer group, (Sp 2 ) p , as a means of linking the active agent A to Z, where Sp 2 is selected from the group consisting of: —C 1-12 alkyl-, —C 3-12 cycloalkyl-, —(C 1-8 alkyl)-(C 3-12 cycloalkyl)-(C 0-8 alkyl)-, —(CH 2 ) 1-12 O—, (—(CH 2 ) 1-6 —O—(CH 2 ) 1-6 —) 1-12 , (—(CH 2 ) 1-4 —NH—(CH 2 ) 1-4 ) 1-12 —, (—(CH 2 ) 1-4 —O—(CH 2 ) 1-4 ) 1-12 —O—, (—(CH 2 ) 1-4 —O—(CH 2 ) 1-4 —) 1-12 O—(CH 2 ) 1-12 —, —(CH 2 ) 1-4 —O—(CH

- the polymeric portion of the compounds is poly-hydroxyethylmethacryloyl phosphorylcholine (poly-HEMA-PC).

- poly-HEMA-PC poly-hydroxyethylmethacryloyl phosphorylcholine

- the polymer is prepared from a mixture of monomers, at least half of which are hydroxyethylmethacryloyl phosphorylcholine (i.e., HEMA-PC).

- m is an integer that may be selected from the following ranges: 2-30, 30-100, 100-500, 500-1,000 and 1,000-2,000.

- X is a group selected from hydroxyl, thiol, disulfide, dithiopyridyl, aldehyde, aldehyde hydrate, ketone, thione, acetal, ketal, —CH(OR 1 ) 2 , hemiacetal, hemiketal, monothioketal, dithiohemiketal, dithioketal, epoxide, thioepoxide, glyoxal, diones, amide, hydrazide, carboxyl, carboxylic acid ester, orthoester, N-hydroxysuccinimide ester, succinimidyl, maleimidyl, 1-benzotriazolyl, —CO 2 -succinimidyl, —CO 2 -maleimidyl, imidoester, guanido, and —CO 2 -(1-benzotriazolyl); where R 1 is C 1-6 alky

- X is a group selected from amine, urea, carbamate, carbonate, thiourea, thiocarbamate, isocyanate, isothiocyanate, sulfone, chloroethylsulfone, —O(C ⁇ O)—CH 2 —I, —O(C ⁇ O)—CH 2 —Br, —NH(C ⁇ O)—CH 2 —I, —NH(C ⁇ O)—CH 2 —Br, —(C ⁇ O)—CH 2 —I, and —(C ⁇ O)—CH 2 —Br.

- X is a group selected from alpha-beta substituted carbonyl, alpha-beta substituted carboxyl, acryloyl, acrylate, methacrylate, acrylamide, vinylsulfone, and vinylpyridine.

- n 1

- n is 0 and -(Sp 1 ) 0 - is a covalent bond.

- said biologically active agent is selected from the group consisting of: drugs, vaccines, antibodies, antibody fragments, vitamins and cofactors, polysaccharides, carbohydrates, steroids, lipids, fats, proteins, peptides, polypeptides, nucleotides, oligonucleotides, polynucleotides, and nucleic acids (e.g., mRNA, tRNA snRNA, RNAi, DNA, cDNA, antisense constructs, ribozymes, etc).

- drugs e.g., mRNA, tRNA snRNA, RNAi, DNA, cDNA, antisense constructs, ribozymes, etc.

- said biologically active agent is selected from the group consisting of: agalsidase, alefacept, aspariginase, amdoxovir (DAPD), antide, becaplermin, botulinum toxin including types A and B and lower molecular weight compounds with botulinum toxin activity, calcitonins, cyanovirin, denileukin diftitox, erythropoietin (EPO) (i.e., 166 amino acid form and mature 165 amino acid form of human EPO), EPO agonists, dornase alpha, erythropoiesis stimulating protein (NESP), coagulation factors such as Factor V, Factor VII, Factor VIIa, Factor VIII, Factor IX, Factor X, Factor XII, Factor XIII, von Willebrand factor; ceredase, cerezyme, alpha-glucosidase, collagen, cyclospor

- Exemplary monoclonal antibodies include etanercept (a dimeric fusion protein consisting of the extracellular ligand-binding portion of the human 75 kD TNF receptor linked to the Fc portion of IgG1), abciximab, adalimumab, afelimomab, alemtuzumab, antibody to B-lymphocyte, atlizumab, basiliximab, bevacizumab, biciromab, bertilimumab, CDP-484, CDP-571, CDP-791, CDP-860, CDP-870, cetuximab, clenoliximab, daclizumab, eculizumab, edrecolomab, efalizumab, epratuzumab, fontolizumab, gavilimomab, gemtuzumab ozogamicin, ibritumomab tiuxetan

- said biologically active agent is selected from the group consisting of: erythropoietin, granulocyte colony stimulating factor (G-CSF), interferon alpha, interferon beta, human growth hormone, and imiglucerase.

- G-CSF granulocyte colony stimulating factor

- said biologically active agent is selected from the group consisting of: tacrine, memantine, rivastigmine, galantamine, donepezil, levetiracetam, repaglinide, atorvastatin, alefacept, tadalafil, vardenafil, sildenafil, fosamprenavir, oseltamivir, valacyclovir and valganciclovir, abarelix, adefovir, alfuzosin, alosetron, amifostine, amiodarone, aminocaproic acid, aminohippurate sodium, aminoglutethimide, aminolevulinic acid, aminosalicylic acid, amlodipine, amsacrine, anagrelide, anastrozole, aprepitant, aripiprazole, asparaginase, atazanavir, atomoxetine, anthracyclines, bexarotene

- said biologically active agent is selected from the group consisting of: aminohippurate sodium, amphotericin B, doxorubicin, aminocaproic acid, aminolevulinic acid, aminosalicylic acid, metaraminol bitartrate, pamidronate disodium, daunorubicin, levothyroxine sodium, lisinopril, cilastatin sodium, mexiletine, cephalexin, deferoxamine, and amifostine.

- said biologically active agent is a protein or polypeptide.

- said protein or polypeptide comprises a non-naturally occurring amino acid.

- Another group of embodiments is directed to a method of preparing a compound of formulas (Ia) through (Vb) according to any of the above embodiments,

- Another group of embodiments is directed to a pharmaceutical composition

- a pharmaceutical composition comprising a compound of formulas (Ib), (IIb), (IIIb) (IVb) or (Vb) according to any of the above embodiments.

- Another group of embodiments is directed to a pharmaceutical composition further comprising a second biologically active agent.

- Another group of embodiments is directed to a method of treatment compromising administering to a patient in need thereof a compound of formulas (Ib), (IIb), (IIIb) (IVb) or (Vb) according to any of the above embodiments.

- the invention provides for compounds or compositions (e.g., pharmaceutical compositions) that include a biologically active agent bonded (e.g., covalently bonded) to a phosphorylcholine containing polymer.

- a biologically active agent bonded (e.g., covalently bonded) to a phosphorylcholine containing polymer.

- the invention also contemplates a single phosphorylcholine bonded to a biologically active agent.

- the phosphorylcholine is an oxyethylphosphorylcholine, for example, an acryloyloxyethylphosphorylcholine.

- the invention includes methods of treating a human or animal patient which include administering to a patient in need thereof a phosphorylcholoine containing polymer of the invention bonded to a biologically active agent or administering to a patient in need thereof a pharmaceutical composition containing a phosphorylcholoine containing polymer bonded to a biologically active agent.

- the invention provides for methods of increasing the half-life of a biologically active agent in a patient which include bonding a phosphorylcholine (e.g., phosphorylcholine containing polymer) to a biologically active agent in accordance with the invention.

- a phosphorylcholine e.g., phosphorylcholine containing polymer

- the phosphorylcholoine containing polymer may be any useful type of polymer.

- the phosphorylcholine containing polymer may be a linear polymer and the phosphorylcholine containing polymer may be a branched polymer, each as is understood by a practitioner of skill in the art.

- the polymers of the invention may be of any useful size.

- the polymers are greater than 0.5 kDa in size, for example, greater than 4 kDa in size.

- the phosphorylcholine polymer has a molecular weight between about 0.5 kDa and about 800 kDa, for example, between about 0.5 kDa and about 400 kDa (e.g., between about 0.5 kDa and about 200 kDa).

- Polymers of the invention are contemplated which contain as few as two phosphorylcholine groups.

- polymers of the invention are contemplated which contain two, three, four, five, six, seven and eight or more phosphorylcholine groups.

- biologically active agents are disclosed in the present application and, accordingly, the invention encompasses each of the biologically active agents disclosed herein bonded to the phosphorylcholoine containing polymers of the invention.

- the biologically active agents are typically bonded to the phosphorylcholoine containing polymers of the invention by a covalent bond. Any useful covalent bonding may be employed in the invention.

- the biologically active agents may be bonded to the phosphorylcholoine containing polymers through a covalent bond at least one of an amino group, a hydroxyl group, a sulfhydryl group and a carboxyl group of the biologically active agent.

- the phosphorylcholine polymer is covalently bonded to a spacer and the biologically active agent is covalently bonded to the spacer. That is, in certain instances it may be useful to attach a biologically active agent to the phosphorylcholoine containing polymers of the invention using a spacer such as (Steve, may want to mention a few linker types here). For example, covalently bonding a phosphorylcholoine containing polymer to a biologically active agent by use of a spacer may reduce steric hindrance which prevents or reduces the efficiency of the bonding (i.e., the chemical bonding reaction) that provides for the coupling of the phosphorylcholoine containing polymer to the biologically active agent.

- a spacer such as (Steve, may want to mention a few linker types here).

- covalently bonding a phosphorylcholoine containing polymer to a biologically active agent by use of a spacer may reduce steric hindrance which prevents or reduces

- the biologically active agent is a protein, i.e., a therapeutic protein.

- the biologically active agent is a human protein such as a human cytokine.

- the biologically active agents of the invention may be obtained from any useful source and by any useful methodology.

- the biologically active agents of the invention such as human proteins (e.g., human cytokines such as erythropoietin, G-CSF, interferons, GM-CSF and human enzymes and human hormones) and antibodies, may be obtained by heterologous gene expression in bacteria, yeast and cell cultures such as mammalian cell cultures, insect cell cultures, plant cell cultures and avian cell cultures as is understood in the art.

- the proteins of the invention may also be obtained from transgenic organisms such as transgenic avians (e.g., transgenic chickens, transgenic quail and transgenic turkey), transgenic goats, transgenic cows and transgenic plants as is understood in the art. It is also contemplated that human proteins for use as disclosed herein can be produced by gene activation in human cell lines as is understood in the art. Many of the biologically active agents can be obtained from natural sources or can be obtained from organic synthesis reactions as is understood in the art.

- FIG. 1 shows the amino acid sequence (165 amino acids) of human erythropoietin (EPO).

- FIG. 2 shows the amino acid sequence (174 amino acids) of human granulocyte colony stimulating factor (G-CSF).

- FIGS. 3 and 4 show an HPLC chromatogram illustrating the conjugation of an aldehyde functionalized polymer of the invention to G-CSF.

- FIGS. 5 , 6 and 7 show an HPLC chromatogram illustrating the conjugation of an aldehyde functionalized polymer of the invention to EPO.

- FIG. 8 shows an HPLC chromatogram illustrating the conjugation of a NHS functionalized polymer of the invention to G-CSF.

- FIGS. 9 and 10 show an HPLC chromatogram illustrating the conjugation of a NHS functionalized polymer of the invention to EPO.

- FIG. 11 shows an HPLC chromatogram illustrating the conjugation of a NHS functionalized polymer of the invention to Interferon alpha.

- FIG. 12 shows an HPLC chromatogram illustrating the conjugation of a NHS functionalized polymer of the invention to G-CSF.

- FIG. 13 shows an HPLC chromatogram illustrating the conjugation of a NHS functionalized polymer of the invention to somatostatin.

- FIG. 14 shows an HPLC chromatogram illustrating the conjugation of an aldehyde functionalized branched polymer of the invention to EPO.

- Water-soluble polymer refers to a polymer that is soluble in water at room temperature.

- a solution of a water-soluble polymer may transmit at least about 75%, more preferably at least about 95% of light, transmitted by the same solution after filtering.

- a water-soluble polymer or segment thereof may be at least about 35%, at least about 50%, about 70%, about 85%, about 95% or 100% (by weight of dry polymer) soluble in water.

- Molecular weight in the context of the polymer can be expressed as either a number average molecular weight or a weight average molecular weight. Unless otherwise indicated, all references to molecular weight herein refer to the weight average molecular weight. Both molecular weight determinations, number average and weight average, can be measured using gel permeation chromatography or other liquid chromatography techniques. Other methods for measuring molecular weight values can also be used, such as the use of end-group analysis or the measurement of colligative properties (e.g., freezing-point depression, boiling-point elevation, or osmotic pressure) to determine number average molecular weight, or the use of light scattering techniques, ultracentrifugation or viscometry to determine weight average molecular weight.

- colligative properties e.g., freezing-point depression, boiling-point elevation, or osmotic pressure

- the polymeric reagents of the invention are typically polydisperse (i.e., number average molecular weight and weight average molecular weight of the polymers are not equal), possessing low polydispersity values of preferably less than about 1.5, as judged by gel permeation chromatography.

- the polydispersities may be in the range of about 1.4 to about 1.2, more preferably less than about 1.15, still more preferably less than about 1.10, yet still more preferably less than about 1.05, and most preferably less than about 1.03.

- a or “an” entity refers to one or more of that entity; for example, a compound refers to one or more compounds or at least one compound.

- a compound refers to one or more compounds or at least one compound.

- the terms “a” (or “an”), “one or more”, and “at least one” can be used interchangeably herein.

- compound as used herein is intended to encompass not only the specified molecular entity but also its pharmaceutically acceptable, pharmacologically active derivatives, including, but not limited to, salts, prodrug conjugates such as esters and amides, metabolites, hydrates, solvates and the like.

- protected refers to the presence of a group (i.e., the protecting group) that prevents or blocks reaction of a particular chemically reactive functional group in a molecule under certain reaction conditions.

- Protecting group will vary depending upon the type of chemically reactive group being protected as well as the reaction conditions to be employed and the presence of additional reactive or protecting groups in the molecule, if any.

- protecting groups known in the art, such as those found in the treatise by Greene et al., “Protective Groups In Organic Synthesis,” 3 rd Edition, John Wiley and Sons, Inc., New York, 1999.

- spacer and “spacer group” are used interchangeably herein to refer to an atom or a collection of atoms optionally used to link interconnecting moieties such as a terminus of a water-soluble polymer and a reactive group of a biologically active agent and a reactive group.

- a spacer may be hydrolytically stable or may include a hydrolytically susceptible or enzymatically degradable linkage.

- Alkyl refers to linear or branched hydrocarbon chains. Non-limiting examples of alkyl groups include methyl, ethyl, propyl, butyl, pentyl, 1-methylbutyl (i.e., 2-pentyl), 1-ethylpropyl (i.e., 3-pentyl), 3-methylpentyl, and the like.

- alkyl is also used to indicate a hydrocarbon group that may be linear or branched that may have two or more functionalities appended; and it is understood that “alkyl” includes alkylene when two functionalities are appended. As used herein, “alkyl” does not include cycloakyl unless expressly stated otherwise.

- alkyl groups may have a range of sizes that size range may be indicated by indicating the number of carbon atoms present in the alkyl group (e.g., C 1-3 alkyl or C 1 to C 3 for a one to three carbon atom containing alkyl group).

- a range includes the value of “0” (e.g. C 0-3 alkyl) the group is not present in one embodiment, and if intervening between two groups, it constitutes a covalent bond.

- alkoxy refers to the above alkyl groups linked, to oxygen.

- Poly(acryloyloxyethyl phosphorylcholine) containing polymer denotes a polymer of acrylic acid containing at least one acryloyloxyethyl phosphorylcholine monomer such as 2-methacryloyloxyethyl phosphorylcholine (i.e., 2-methacryloyl-2′-trimethylammonium ethyl phosphate).

- carboxyalkyl means an alkyl group (as defined herein) substituted with a carboxy group.

- carboxycycloalkyl means an cycloalkyl group (as defined herein) substituted with a carboxy group.

- alkoxyalkyl means an alkyl group (as defined herein) substituted with an alkoxy group.

- carboxy employed herein refers to carboxylic acids and their esters.

- haloalkyl and “haloalkoxy” are meant to include monohaloalkyl(oxy) and polyhaloalkyl(oxy).

- C 1 -C 6 haloalkyl is mean to include trifluoromethyl, 2,2,2-trifluoroethyl, 4-chlorobutyl, 3-bromopropyl, and the like.

- Fluoro-substituted alkyl refers to an alkyl group where one, some, or all hydrogen atoms have been replaced by fluorine.

- Cytoke in the context of this invention is a member of a group of protein signaling molecules that may participate in cell-cell communication in immune and inflammatory response. Cytokines are typically small, water-soluble glycoproteins that have a mass of about 8-35 kDa.

- “Therapeutic proteins” are peptides or proteins that include an amino acid sequence which in whole or in part makes up a drug and can be used in human or animal pharmaceutical applications. Numerous therapeutic proteins are known to practitioners of skill in the art including, without limitation, those disclosed herein.

- Phosphorylcholine containing polymer is a polymer that contains phosphorylcholine. It is specifically contemplated that in each instance where a phosphorylcholine containing polymer is specified in this application for a particular use, a single phosphorylcholine can also be employed in such use.

- Cycloalkyl refers to a cyclic hydrocarbon group that contains from about 3 to 12, from 3 to 10, or from 3 to 7 endocyclic carbon atoms. Cycloalkyl groups include fused, bridged and spiro ring structures.

- endocyclic refers to an atom or group of atoms which comprise part of a cyclic ring structure.

- exocyclic refers to an atom or group of atoms which are attached but do not define the cyclic ring structure.

- Cyclic alkyl ether refers to a 4 or 5 member cyclic alkyl group having 3 or 4 endocyclic carbon atoms and 1 endocyclic oxygen or sulfur atom (e.g., oxetane, thietane, tetrahydrofuran, tetrahydrothiophene); or a 6 to 7 member cyclic alkyl group having 1 or 2 endocyclic oxygen or sulfur atoms (e.g., tetrahydropyran, 1,3-dioxane, 1,4-dioxane, tetrahydrothiopyran, 1,3-dithiane, 1,4-dithiane, 1,4-oxathiane).

- Alkenyl refers to an unsaturated linear or branched hydrocarbon group containing at least one carbon-carbon double bond.

- alkenyl groups include ethenyl, n-propenyl, isopropenyl, n-butenyl, isobutenyl, octenyl, decenyl, tetradecenyl, and the like.

- Aryl refers to a cyclic aromatic group having one or more aromatic rings, each having 5 or 6 endocyclic atoms independently selected from carbon, oxygen, nitrogen and sulfur. Aryl rings may be fused.

- Non-limiting examples of aryl groups include naphthyl, and phenyl.

- aryl includes carbocyclic aryl, in which all endocyclic atoms of the aromatic group are carbon atoms, and heteroaryl groups.

- Heteroaryl refers to an aryl group having one or more heteroatoms (for example nitrogen, oxygen and/or sulfur) in at least one ring.

- Non-limiting examples include pyrrole, furanyl, thienyl, pyridyl, oxazolyl, thiazolyl, benzofuranyl, and benzothienyl.

- Electrophile refers to an ion or atom or collection of atoms, which may be ionic, having an electrophilic center, i.e., a center that is electron seeking, capable of reacting with a nucleophile.

- An electrophile or electrophilic reagent is a reagent that forms a bond to its reaction partner (the nucleophile) by accepting both bonding electrons from that reaction partner.

- Nucleophile refers to an ion or atom or collection of atoms, which may be ionic, having a nucleophilic center, i.e., a center that is seeking an electrophilic center or with an electrophile.

- a nucleophile or nucleophilic reagent is a reagent that forms a bond to its reaction partner (the electrophile) by donating both bonding electrons.

- a “nucleophilic group” refers to a nucleophile after it has reacted with a reactive group. Non limiting examples include amino, hydroxyl, alkoxy, haloalkoxy and the like.

- PC phosphatphorylcholine

- the phosphorylcholine is a zwitterionic group and includes salts (such as inner salts), and protonated and deprotonated forms thereof.

- Reactive group refers to a functional group that is capable of forming a covalent linkage consisting of one or more bonds to a biologically active agent. Nonlimiting examples include those illustrated in Table 1.

- Maleimido refers to a pyrrole-2,5-dione-1-yl group having the structure

- hydrolytically susceptible linkage refers to a chemical linkage or bond, which may be a covalent bond that undergoes hydrolysis under physiological conditions. The tendency of a bond to hydrolyze may depend not only on the general type of linkage connecting two central atoms between which the bond is severed, but also on the substituents attached to these central atoms.

- hydrolytically susceptible linkages include esters of carboxylic acids, phosphate esters, acetals, ketals, acyloxyalkyl ether, imines, orthoesters, and some amide linkages.

- an “enzymatically degradable linkage” means a linkage that is subject to degradation by one or more enzymes. Some hydrolytically susceptible linkages may also be enzymatically degradable. For example esterases may act on esters of carboxylic acid or phosphate esters, and proteases may act on peptide bonds and some amide linkages.

- active agent and “biologically active agent” are used interchangeably herein and are defined to include any agent, drug, compound, or mixture thereof that provides some local or systemic physiological or pharmacologic effect that can be demonstrated in vivo or in vitro.

- Non-limiting examples include drugs, vaccines, antibodies, antibody fragments, vitamins and cofactors, polysaccharides, carbohydrates, steroids, lipids, fats, proteins, peptides, polypeptides, nucleotides, oligonucleotides, polynucleotides, and nucleic acids (e.g., mRNA, tRNA snRNA, RNAi, DNA, cDNA, antisense constructs, ribozymes, etc).

- drugs vaccines, antibodies, antibody fragments, vitamins and cofactors, polysaccharides, carbohydrates, steroids, lipids, fats, proteins, peptides, polypeptides, nucleotides, oligonucleotides, polynucleotides, and nucle

- solvate means a compound of the invention or a salt, thereof, that further includes a stoichiometric or non-stoichiometric amount of a solvent bound by non-covalent intermolecular forces in an amount of greater than about 0.3% when prepared according to the invention.

- hydrate as used herein means a compound of the invention or a salt thereof, that further includes a stoichiometric or non-stoichiometric amount of water bound by non-covalent intermolecular forces. Hydrates are formed by the combination of one or more molecules of water with one of the substances in which the water retains its molecular state as H 2 O, such combination being able to form one or more hydrate.

- isomers refer to certain compounds of the present invention which possess asymmetric carbon atoms (optical centers) or double bonds; the racemates, diastereomers, geometric isomers and individual isomers (e.g., separate enantiomers). All of these are encompassed by the term “isomers” within the scope of the present invention.

- “naturally occurring amino acids” found in proteins and polypeptides are L-alanine, L-arginine, L-asparagine, L-aspartic acid, L-cysteine, L-glutamine, L-glutamic acid, L-glycine, L-histidine, L-isoleucine, L-leucine, L-lysine, L-methionine, L-phenylalanine, L-proline, L-serine, L-threonine, L-tryptophan, L-tyrosine, and or L-valine.

- “Non-naturally occurring amino acids” found in proteins are any amino acid other than those recited as naturally occurring amino acids.

- Non-naturally occurring amino acids include, without limitation, the D isomers of the naturally occurring amino acids, and mixtures of D and L isomers of the naturally occurring amino acids.

- Other amino acids such as 4-hydroxyproline, desmosine, isodesmosine, 5-hydroxylysine, epsilon-N-methyllysine, 3-methylhistidine, although found in naturally occurring proteins, are considered to be non-naturally occurring amino acids found in proteins for the purpose of this disclosure as they are generally introduced by means other than ribosomal translation of mRNA.

- Linear in reference to the geometry, architecture or overall structure of a polymer, refers to polymer single monomer derived backbone.

- Branched in reference to the geometry, architecture or overall structure of a polymer, refers to polymer having 2 or more polymer “arms” extending from a single group, such as an L group that may be derived from an initiator employed in an atom transfer radical polymerization reaction.

- a branched polymer may possess 2 polymer arms, 3 polymer arms, 4 polymer arms, 5 polymer arms, 6 polymer arms, 8 polymer arms or more.

- compounds having three or more polymer arms extending from a single linear group are denoted as having a “comb” structure or “comb” architecture.

- Formked refers to a multifunctional chemical structure wherein multiple functional groups (reactive groups or biologically active agents) in addition to one or more polymer arms are attached (either directly or through one or more atoms) to a chemical group such as an L group that may be derived from an initiator employed in an atom transfer radical polymerization reaction.

- “Pharmaceutically acceptable” composition or “pharmaceutical composition” refers to a composition comprising a compound of the invention and a pharmaceutically acceptable excipient or pharmaceutically acceptable excipients.

- salt includes, without limitation, acid addition salts including hydrochlorides, hydrobromides, phosphates, sulphates, hydrogen sulphates, alkylsulphonates, arylsulphonates, acetates, benzoates, citrates, maleates, fumarates, succinates, lactates, and tartrates; salts of alkali metal cations such as Na + , K + , Li + (e.g., NaCl, KCl) organic amine salts or alkali earth metal salts such as Mg or Ca salts.

- alkali metal cations such as Na + , K + , Li + (e.g., NaCl, KCl) organic amine salts or alkali earth metal salts such as Mg or Ca salts.

- “Pharmaceutically acceptable excipient” and “pharmaceutically acceptable carrier” refer to an excipient that can be included in the compositions of the invention and that causes no significant adverse toxicological effect on the patient.

- Non-limiting examples of pharmaceutically acceptable excipients include water, NaCl, normal saline solutions, lactated Ringer's, normal sucrose, normal glucose and the like.

- “Patient” or “subject in need thereof” refers to a living organism suffering from or prone to a condition that can be prevented or treated by administration of a pharmaceutical composition as provided herein.

- Non-limiting examples include humans, other mammals and other non-mammalian animals.

- “Therapeutically effective amount” refers to an amount of a conjugated biologically active agent or of a pharmaceutical composition useful for treating, ameliorating, or preventing an identified disease or condition, or for exhibiting a detectable therapeutic or inhibitory effect. The effect can be detected by any assay method known in the art.

- the “biological half-life” of a substance is a pharmacokinetic parameter which specifies the time required for one half of the substance to be removed from an organism following introduction of the substance into the organism.

- One aspect of the present invention relates to compounds of formula (Ia): (X-(Sp 1 ) n ) a -L-(K) b (Ia) where

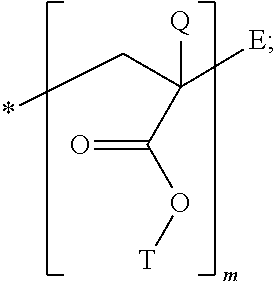

- K is a group of the formula

- Another aspect of the present invention relates to compounds of formula (Ib): (A-Z-(Sp 1 ) n ) a -L-(K) b (Ib) where

- K is a group of the formula

- One aspect of the present invention is directed to compound of formula (Ia) or formula (Ib) where a and b are both 1 (e.g., or a salt, hydrate, or isomer thereof).

- Such embodiments include for example compounds of formula (IIa) and compounds of formula (IIb), respectively.

- One embodiment of this aspect relates to novel compounds of formula (IIa), or a salt, hydrate, or isomer thereof.

- Another embodiment relates to a zwitterionic compound of formula (IIb) or a salt, hydrate, or isomer thereof:

- variable groups present in compounds of formulas (IIa) and (IIb) are as defined for compounds of formulas (Ia) and (Ib) and embodiments thereof, respectively.

- the present invention is also directed to compounds having more complex architectures.

- Such architectures include branched compounds, forked compounds, branched and forked compounds.

- Branched polymer compounds having multiple polymer arms may also have comb or star architectures. In theory, branched compounds having two or more polymer arms may aid in promoting water solubility without unduly hindering the interactions of an attached biologically active agent.

- An aspect of the present invention is directed to forked compounds of formula (Ia) or formula (Ib), where a is an integer greater than 1.

- b is an integer greater than 1 and the compounds are branched compounds having more than one polymer arm in the form of the group K.

- the polymeric portion of the molecule may be poly-hydroxyethylmethacryloyl phosphorylcholine, regardless of the value of a (e.g., a may be 1, 2, 3, or 4).

- both a and b are integers greater than 1 and the compounds are branched and forked compounds.

- L comprises one carbon atom; or in another embodiment 2 carbon atoms, or in another embodiment L comprises 3 or more carbon atoms.

- L comprises 2 carbon atoms, or in another embodiment 3 carbon atoms, or in another embodiment 4 carbon atoms.

- L comprises 3 carbon atoms, or in another embodiment 4 carbon atoms, or in another embodiment 5 carbon atoms.

- L comprises 4 carbon atoms, or in another embodiment 5 carbon atoms, or in another embodiment 6 carbon atoms.

- variable groups present in compounds of formulas (IIIa), (IVa) or (Va) are as defined for compounds of formula (Ia) or embodiments thereof.

- all groups present in compounds of formulas (IIIb), (IVb) or (Vb) are as defined for compounds of formula (Ib) or embodiments thereof.

- the polymeric portion of the compounds comprises poly(2-methacryloyloxyethyl phosphorylcholine) also referred to as pMPC, poly-hydroxyethylmethacryloyl phosphorylcholine, pHEMA-PC or poly-HEMA-PC.

- the polymeric portion of the molecule consists of a poly-HEMA-PC polymer, e.g., K is a group of the formula

- T is a phosphorylcholine group

- E is independently selected from the group consisting of Br, Cl, I, —NH 2 , —NH(C 1-4 alkyl), —N(C 1-4 alkyl) 2 , —OH, —O—(C 1-4 alkyl), and —O—(C 1-4 fluoro-substituted alkyl); and m is an integer selected based on the desired molecular weight of the polymeric portion of a compound of formulas (Ia) through (Vb).

- m is an integer ranging from about 2 to about 30, or from about 30 to about 100, or from about 20 to about 200, or alternatively, from about 100 to about 500. In another embodiment, m is an integer ranging from about 500 to about 1,000; and in still another embodiment m is an integer ranging from about 1,000 to about 2,000.

- Compounds of formulas (Ia) (IIa), (IIIa), (IVa), or (Va) may also have the value of m adjusted such that the molecular weight range (in Daltons) of the compound is from about 500 to about 2000, or from 2,000 to about 5,000, or from about 5,000 to about 10,000, or from about 10,000 to about 50,000, or from about 50,000 to about 100,000, or from about 100,000 to about 200,000.

- Exemplary molecular weights for compounds of formulas (Ia) (IIa), (IIIa), (IVa), or (Va) include about 2,000 Daltons, about 2,200 Daltons, about 2,500 Daltons, about 3,000 Daltons, about 4,000 Daltons, about 4,400 Daltons, about 5,000 Daltons, about 6,000 Daltons, about 7,000 Daltons, about 7,500 Daltons, about 8,000 Daltons, about 9,000 Daltons, about 10,000 Daltons, about 11,000 Daltons, about 12,000 Daltons, about 13,000 Daltons, about 14,000 Daltons, about 15,000 Daltons, about 20,000 Daltons, about 22,500 Daltons, about 25,000 Daltons, about 30,000 Daltons, about 40,000 Daltons, about 50,000 Daltons, about 60,000 Daltons, about 75,000 Daltons, about 80,000 Daltons, about 90,000 Daltons, about 100,000 Daltons, about 120,000 Daltons, about 140,000 Daltons about 150,000 Daltons and about 175,000 Daltons.

- m is an integer ranging from about 2 to about 30, or from about 30 to about 100, or from about 20 to about 200, or alternatively, from about 100 to about 500. In some embodiments, m is an integer ranging from about 500 to about 1,000, and in other embodiments, m is an integer ranging from about 1,000 to about 2,000.

- Compounds of formulas (Ib), (IIb), (IIIb), (IVb), or (Vb) may also have the value of m adjusted such that the molecular weight range (in Daltons), excluding the molecular weight of the biologically active agent A, is from about 2,000 to about 5,000, or from about 5,000 to about 10,000, or from about 10,000 to about 50,000, or from about 50,000 to about 100,000, or from about 100,000 to about 200,000.

- Exemplary molecular weights for compounds of formulas (Ib) (IIb), (IIIb), (IVb), or (Vb) excluding the molecular weight of the biologically active agent A include about 2,000 Daltons, about 2,200 Daltons, about 2,500 Daltons, about 3,000 Daltons, about 4,000 Daltons, about 4,400 Daltons, about 5,000 Daltons, about 6,000 Daltons, about 7,000 Daltons, about 7,500 Daltons, about 8,000 Daltons, about 9,000 Daltons, about 10,000 Daltons, about 11,000 Daltons, about 12,000 Daltons, about 13,000 Daltons, about 14,000 Daltons, about 15,000 Daltons, about 20,000 Daltons, about 22,500 Daltons, about 25,000 Daltons, about 30,000 Daltons, about 40,000 Daltons, about 50,000 Daltons, about 60,000 Daltons, about 75,000 Daltons, about 80,000 Daltons, about 90,000 Daltons, about 100,000 Daltons, about 120,000 Daltons, about 140,000 Daltons about 150,000 Daltons and about 175,000 Daltons

- the value of m may be selected such that the molecular weight of the compounds excluding the weight of the active agent “A” when present, is from about 2,000 to about 300,000 Daltons.

- Other molecular weight ranges for compounds of formula (Ia) or (Ib) where b is greater than or equal to 3 are from about 5,000 to about 10,000, or from about 10,000 to about 50,000, or from about 50,000 to about 100,000, or from about 100,000 to about 200,000 or from about 200,000 to about 250,000 or from about 250,000 to about 300,000 Daltons, excluding the weight of the active agent “A” when present.

- the length of the polymer in compounds of formula (Ia) through (Vb), and thus the mass, may be varied over at least the above stated ranges.

- the variation in the size/mass of compounds of formula (Ia) through (Vb) Ib may be controlled to give preparations having narrowly dispersed ranges, or alternatively, broadly dispersed ranges of size/mass.

- X is a reactive group or a protected form thereof that can react with nucleophiles or electrophiles.

- X is a group capable of reacting with a nucleophile or electrophile present in a biologically active agent.

- X is a group capable of reacting with a functionality selected from an aldehyde, a ketone, an amine, a carboxyl, a hydroxyl, guanido or thiol group of a biologically active agent to form a covalent linkage between the biologically active agent and the L group to which X was attached.

- the linkage between the biologically active agent and L may include one or more atoms derived from X, one or more atoms derived from the reaction of A with X, or atoms of an Sp1 group if present.

- the linkage between L and the biologically active agent may be a direct covalent bond where X is a group that may be displaced from L, such as a by a nucleophile of the biologically active agent acting in a S N 1 or S N 2 nucleophilic substitution reaction.

- X is selected from the group consisting of: hydroxyl, thiol, disulfide, dithiopyridyl, aldehyde, aldehyde hydrate, ketone, thione, acetal, ketal, —CH(OR 1 ) 2 , hemiacetal, hemiketal, monothioketal, dithiohemiketal, dithioketal, epoxide, thioepoxide, glyoxal, diones, amide, hydrazide, carboxyl, carboxylic acid ester, orthoester, N-hydroxysuccinimide ester, succinimidyl, maleimidyl, 1-benzotriazolyl, —CO 2 -succinimidyl, —CO 2 -maleimidyl, imidoester, guanido,

- X is a group selected from protected and unprotected forms of: hydroxyl, thiol, disulfide, dithiopyridyl, aldehyde, aldehyde hydrate, ketone, thione, acetal, ketal, —CH(OR 1 ) 2 , hemiacetal, hemiketal, monothioketal, dithiohemiketal, dithioketal, epoxide, glyoxals, diones, amide, hydrazide, carboxyl, carboxylic acid ester, orthoester, succinimidyl, maleimidyl, 1-benzotriazolyl, —CO 2 -succinimidyl, —CO 2 -maleimidyl, and —CO 2 -(1-benzotriazolyl); wherein R 1 is C 1 -

- X is a group selected from protected and unprotected forms of: ether, thioether, amine, urea, carbamate, carbonate, thiourea, thiocarbamate, isocyanate, isothiocyanate, sulfone, and chloroethylsulfone.

- X is alpha-beta substituted carbonyl, C 2 -C 12 alkenyl, acryloyl, acrylate, methacrylate, acrylamide, vinlysulfone and vinylpyridine.

- an X group contains a double bond that cannot be present in the polymerization reactions, such as where X comprises a vinyl pyridine group, an alpha-beta unsaturated carbonyl, an alpha-beta ester, vinlysulfone or an alpha-beta amide

- the group may be introduced into the compounds following any polymerization process that creates the polymeric portion of the compounds of the invention. This may be accomplished, for example, through a bifunctional agent having a X group and a group capable of reacting with a functionality attached to the L group, such as an NHS ester, group both appended to an -(Sp 1 )- group.

- Sp 1 is selected from the group consisting of: an alkyl ether and an alkyl ester of an alkyl carboxylic acid.

- Sp 1 is selected from the group consisting of: —C 1-12 alkyl-, —C 3-12 cycloalkyl-, —(C 1-8 alkyl)-(C 3-12 cycloalkyl)-(C 0-8 alkyl)-, —(CH 2 ) 1-12 O—, (—(CH 2 ) 1-6 —O—(CH 2 ) 1-6 —) 1-12 —, (—(CH 2 ) 1-4 —NH—(CH 2 ) 1-4 ) 1-12 —, (—(CH 2 ) 1-4 —O—(CH 2 ) 1-4 ) 1-12 —O—, (—(CH 2 ) 1-4 —O—(CH 2 ) 1-4 —) 1-12 O—(CH 2 ) 1-12 —, —(CH 2 ) 1-12 —(C ⁇ O)—O—, —(CH 2 ) 1-12 —O—(C ⁇ O)—, -(phenyl)-(

- Sp 1 is selected from the group consisting of: —C 1 -C 12 alkyl-, —C 3 -C 12 cycloalkyl-, (—(CH 2 ) 1-6 —O—(CH 2 ) 1-6 —) 1-12 —, (—(CH 2 ) 1-4 —NH—(CH 2 ) 1-4 ) 1-12 —, —(CH 2 ) 1-12 O—, (—(CH 2 ) 1-4 —O—(CH 2 ) 1-4 ) 1-12 —O—, —(CH 2 ) 1-12 —(CO)—O—, —(CH 2 ) 1-12 —(CO)—NH—, —(CH 2 ) 1-12 —O—(CO)—, —(CH 2 ) 1-12 —NH—(CO)—, (—(CH 2 ) 1-4 —O—(CH 2 ) 1-4 ) 1-12 —O—(CH 2 ) 1-12 —, —(CH 2 ) 1

- Z is the product of the reaction between a group present in a biologically active agent and a reactive group (e.g., an X group of a compound of formulas (Ia) (IIa), (IIIa) (IVa) or (Va)) bound to an Sp 1 group when n is 1, or to L when n is 0.

- a reactive group e.g., an X group of a compound of formulas (Ia) (IIa), (IIIa) (IVa) or (Va) bound to an Sp 1 group when n is 1, or to L when n is 0.

- Z is formed from a nucleophile or electrophile present in a biologically active agent and an X group that is capable of forming one or more covalent bonds through a reaction with the nucleophile or electrophile present in the biologically active agent.

- Z is a group resulting from the formation of a covalent bond between an X group and an aldehyde, a ketone, a carboxyl group, an amine, a hydroxyl or a thiol present in a biologically active group.

- Z groups formed from the reaction of some representative X groups and some groups typically found or introduced into biologically active agents are set forth in Table I.

- Reactive X Groups of that may react with a reactive compounds (Ia), (IIa), (IIIa), (IVa), or group (X) to form a Z group.

- Va (shown as appended to —(Sp 1 ) n — ⁇ )

- the biologically active agent, A, of compounds of formula (Ib), (IIb), (IIIb), (IVb), or (Vb) may include a spacer group, (Sp 2 ) p , as a means of linking the active agent, A, to Z.

- p is 0 the spacer group Sp 2 is not present and -Sp 2 - denotes a covalent bond such that the biologically active agent “A” links directly to the Z group by one or more (e.g., a double bond) covalent bonds.

- Sp 2 When n is 1, the spacer group denoted Sp 2 is present between the A and Z groups, and compounds of formula (Ib) may be written as (A(Sp 2 ) p -Z-(Sp 1 ) n ) a -L-(K) b , where all components except (Sp 2 ) and p are as defined for compounds of formula (Ib); and p is 0 or 1.

- Sp 2 spacer groups may comprise an alkyl ether and an alkyl ester of an alkyl carboxylic acid.

- Sp 2 is selected from the group consisting of: —C 1-12 alkyl-, —C 3-12 cycloalkyl-, —(C 1-8 alkyl)-(C 3-12 cycloalkyl)-(C 0-8 alkyl)-, —(CH 2 ) 1-12 O—, (—(CH 2 ) 1-6 —O—(CH 2 ) 1-6 —) 1-12 , (—(CH 2 ) 1-4 —NH—(CH 2 ) 1-4 ) 1-12 —, (—(CH 2 ) 1-4 —O—(CH 2 ) 1-4 ) 1-12 —O—, (—(CH 2 ) 1-4 —O—(CH 2 ) 1-4 —) 1-12 O—(CH 2 ) 1-12 —, —(CH 2 ) 1-12 —(C ⁇ O)—O—, —(CH 2 ) 1-12 alkyl-, —(CH 2 ) 1-12 —(C ⁇ O)—O—,

- Sp 2 spacer groups are selected from: —C 1 -C 12 alkyl-, C 3 -C 12 cycloalkyl, (—(CH 2 ) 1-6 —O—(CH 2 ) 1-6 —) 1-12 —, (—(CH 2 ) 1-4 —NH—(CH 2 ) 1-4 ) 1-12 —, —(CH 2 ) 1-12 O—, (—(CH 2 ) 1-4 —O—(CH 2 ) 1-4 ) 1-12 —O—, —(CH 2 ) 1-12 —(CO)—O—, —(CH 2 ) 1-12 —(CO)—NH—, —(CH 2 ) 1-12 —O—(CO)—, —(CH 2 ) 1-12 —NH—(CO)—, (—(CH 2 ) 1-4 —O—(CH 2 ) 1-4 ) 1-12 —NH—(CO)—, (—(CH 2 ) 1-4 —O—(CH 2 )

- the spacer group Sp 2 when present, is considered to be appended to the biologically active agent, A, for the purpose of synthesizing compounds of formula (Ib) or its sub-embodiments (IIb), (IIIb), (IVb) and (Vb), the Sp 2 spacer group, or a precursor to it, may be introduced into the molecule to form the bond to Z followed by formation of the bond between A and Sp 2 .

- some Sp 2 spacer groups may be considered to be bifunctional agents having both a group capable of reaction with a reactive group X of compounds (Ia), (IIa), (IIIa), (IVa), or (Va) to form a Z group, and a group capable of reacting with a group present in a biologically active agent thereby forming molecules of the form (A(Sp 2 ) p -Z-(Sp 1 ) n ) a -L-(K) b where p is 1.

- a variety of bifunctional reagents that may be employed as a source of Sp 1 and Sp 2 spacer groups are available from commercial suppliers including Pierce Biotechnology, Inc., (Rockford, Ill., USA), (see, e.g., Table II).

- both n and p are 1, or alternatively n is 1 and p is 0, or alternatively n is 0 and p is 1.

- the spacer groups Sp 1 or Sp 2 when present, comprise a hydrolytically susceptible linkage or an enzymatically degradable linkage.

- the hydrolytically susceptible linkages or enzymatically degradable linkages present in Sp 1 or Sp 2 are independently selected from the group consisting of esters of carboxylic acids, phosphate esters, acetals, ketals, acyloxyalkyl ether, imines, orthoesters, disulfides, amides.

- the spacer groups Sp 1 and Sp 2 when present, comprise a hydrolytically susceptible linkage or an enzymatically degradable linkages comprising amino acids, peptides, polypeptides, nucleic acids and oligonucleotides.

- the hydrolytically susceptible or enzymatically degradable linkages are selected from the group consisting of esters of carboxylic acids, phosphate esters, acetals, ketals, acyloxyalkyl ether, imines, orthoesters, disulfides, some amides, peptides, polypeptides, nucleic acids, and oligonucleotides, each of which have a (C 1 -C 6 ) alkyl group on both ends of the susceptible linkage.

- the hydrolytically susceptible or enzymatically degradable linkages present in the Sp 1 and Sp 2 spacers have (C 1 -C 6 ) alkyl groups on each end, and Sp 1 and Sp 2 are selected from the group consisting of —(C 1 -C 6 alkyl)-(C ⁇ O)—O—(C 1 -C 6 alkyl)-, —(C 0 -C 6 alkyl)-PO 4 (H)—(C 0 -C 6 alkyl)- or a salt thereof, —(C 1 -C 6 alkyl)-S—S—(C 1 -C 6 alkyl)-, —(C 1 -C 6 alkyl)-(C ⁇ O)—N—(C 1 -C 6 alkyl)-, or —(C 1 -C 6 alkyl)-C ⁇ N—(C 1 -C 6 alkyl)-.

- the Sp 1 and Sp 2 linkages are selected from the group consisting of —(C 1 -C 6 alkyl)-(aryl)-C ⁇ N—(C 1 -C 6 alkyl)- and —(C 1 -C 6 alkyl)-C ⁇ N-(aryl)-(C 1 -C 6 alkyl)-.

- hydrolytically susceptible linkages are also enzymatically degradable linkages.

- an enzymatically degradable linkage may be placed at any position where a hydrolytically susceptible linkage may be placed.

- the Z group itself may also be a hydrolytically susceptible or enzymatically degradable linkage.

- the Z group may be selected from an amide, an ester or an imine, particularly an imine bearing an adjacent aryl group (i.e., a Schiff base).

- Z may be a carboxylic acid ester, or an amide of a carboxylic acid.

- the active agent, A may be released when it is bound by a hydrolytically susceptible linkage.

- the linkage between A and Z is a hydrolytically susceptible or an enzymatically degradable linkage, which upon cleavage releases A (e.g., Z is a hydrolytically susceptible or an enzymatically degradable linkage).

- A is bound to its Sp 2 spacer group by a hydrolytically susceptible or enzymatically degradable linkage, the cleavage of which releases A.

- the Sp 2 spacer group comprises a hydrolytically susceptible or enzymatically degradable linkage or group, the cleavage of which releases A along with a covalently attached group derived from Sp 2 .

- A is bound directly to Z by a hydrolytically susceptible or enzymatically degradable linkage between A and Z.

- p is 1 and A is a protein or polypeptide

- A is bound to its Sp 2 spacer group by a hydrolytically susceptible or enzymatically degradable linkage between the Sp 2 spacer group and A.

- A is bound directly to Z by a hydrolytically susceptible or enzymatically degradable linkage between Z and the non-naturally occurring amino acid in A.

- A is bound to its Sp 2 spacer group by a hydrolytically susceptible or enzymatically degradable linkage between the Sp 2 spacer group and the non-naturally occurring amino acid in A.

- Biologically active agents denoted by the “A” group of formula (IV) may be broadly selected.

- the biologically active agents may be selected from drugs, vaccines, antibodies, antibody fragment, vitamins and cofactors, polysaccharides, carbohydrates, steroids, lipids, fats, proteins, peptides, polypeptides, nucleotides, oligonucleotides, polynucleotides, and nucleic acids (e.g., mRNA, tRNA snRNA, RNAi, DNA, cDNA, antisense constructs, ribozymes, etc, and combinations thereof).

- the biologically active agents may be selected from proteins, peptides, polypeptides and combinations thereof.

- biologically active agents may be selected from nucleotides, oligonucleotides, polynucleotides, and nucleic acids (e.g., mRNA, tRNA snRNA, RNAi, DNA, cDNA, antisense constructs, ribozymes etc and combinations thereof).

- biologically active agents may be selected from steroids, lipids, fats and combinations thereof.

- the biologically active agent is a therapeutic protein.

- therapeutic proteins are disclosed throughout the application such as, and without limitation, erythropoietin, granulocyte colony stimulating factor (G-CSF), GM-CSF, interferon alpha, interferon beta, human growth hormone, and imiglucerase.

- the biologically active agents may be selected from specifically identified polysaccharide, protein or peptide biologically active agents, including but not limited to: agalsidase, alefacept, aspariginase, amdoxovir (DAPD), antide, becaplermin, botulinum toxin including types A and B and lower molecular weight compounds with botulinum toxin activity, calcitonins, cyanovirin, denileukin diftitox, erythropoietin (EPO), EPO agonists, dornase alpha, erythropoiesis stimulating protein (NESP), coagulation factors such as Factor V, Factor VII, Factor VIIa, Factor VIII, Factor IX, Factor X, Factor XII, Factor XIII, von Willebrand factor; ceredase, cerezyme, alpha-glucosidase, collagen, cyclosporin, alpha defensins,

- Exemplary monoclonal antibodies include etanercept (a dimeric fusion protein consisting of the extracellular ligand-binding portion of the human 75 kD TNF receptor linked to the Fc portion of IgG1), abciximab, adalimumab, afelimomab, alemtuzumab, antibody to B-lymphocyte, atlizumab, basiliximab, bevacizumab, biciromab, bertilimumab, CDP-484, CDP-571, CDP-791, CDP-860, CDP-870, cetuximab, clenoliximab, daclizumab, eculizumab, edrecolomab, efalizumab, epratuzumab, fontolizumab, gavilimomab, gemtuzumab ozogamicin, ibritumomab tiuxetan

- the biologically active agent is a fusion protein.

- the biologically active component may be an immunoglobulin or portion of an immunoglobulin fused to one or more certain useful peptide sequences.

- the biologically active agent may contain an antibody Fc fragment.

- the biologically active agent is a CTLA4 fusion protein.

- the biologically active agent may be an Fc-CTLA4 fusion protein.

- the biologically active agent is a human protein or human polypeptide, for example, a heterologously produced human protein or human polypeptide.

- a human protein or human polypeptide for example, a heterologously produced human protein or human polypeptide.

- Numerous proteins and polypeptides are disclosed herein for which there is a corresponding human form (i.e., the protein or peptide is normally produced in human cells in the human body). Therefore, in one embodiment, the biologically active agent is the human form of each of the proteins and polypeptides disclosed herein for which there is a human form.

- human proteins include, without limitation, human antibodies, human enzymes, human hormones and human cytokines such as granulocyte colony stimulation factor, granulocyte macrophage colony stimulation factor, interferons (e.g., alpha interferons and beta interferons) and erythropoietin.

- human antibodies include, without limitation, human antibodies, human enzymes, human hormones and human cytokines such as granulocyte colony stimulation factor, granulocyte macrophage colony stimulation factor, interferons (e.g., alpha interferons and beta interferons) and erythropoietin.

- human cytokines such as granulocyte colony stimulation factor, granulocyte macrophage colony stimulation factor, interferons (e.g., alpha interferons and beta interferons) and erythropoietin.

- therapeutic proteins which may serve as biologically active agents include, without limitation, factor VIII, b-domain deleted factor VIII, factor VIIa, factor IX, anticoagulants; hirudin, alteplase, tpa, reteplase, tpa, tpa-3 of 5 domains deleted, insulin, insulin lispro, insulin aspart, insulin glargine, long-acting insulin analogs, hgh, glucagons, tsh, follitropin-beta, fsh, gm-csf, pdgh, ifn alpha2, ifn alpha2a, ifn alpha2b, inf-apha1, ifn-beta, inf-beta 1b, ifn-beta 1a, ifn-gamma (e.g., 1 and 2), il-2, il-11, hbsag, ospa, murine mab directed against t-lymphocyte antigen

- therapeutic antibodies that may serve as biologically active agents include, but are not limited, to HERCEPTINTM (Trastuzumab) (Genentech, CA) which is a humanized anti-HER2 monoclonal antibody for the treatment of patients with metastatic breast cancer; REOPROTM (abciximab) (Centocor) which is an anti-glycoprotein IIb/IIIa receptor on the platelets for the prevention of clot formation; ZENAPAXTM (daclizumab) (Roche Pharmaceuticals, Switzerland) which is an immunosuppressive, humanized anti-CD25 monoclonal antibody for the prevention of acute renal allograft rejection; PANOREXTM which is a murine anti-17-IA cell surface antigen IgG2a antibody (Glaxo Wellcome/Centocor); BEC2 which is a murine anti-idiotype (GD3 epitope) IgG antibody (ImClone System); IMC-C225 which is a chimeric anti-EGFR I

- Conjugates of the invention and compositions (e.g., pharmaceutical compositions) containing conjugates of the invention can be used to treat a variety of conditions.

- the invention contemplates that the conjugates of the invention (e.g., phosphorylcholine containing polymer conjugated to a biologically active agent) and compositions containing the conjugates of the invention can be employed to treat such conditions and that such conjugates provide for an enhanced treatment therapy relative to the same biologically active agent not coupled to a phosphorylcholine containing polymer.

- the invention contemplates the treatment of a condition known to be treatable by a certain biologically active agent by treating the condition using the same certain biologically active agent conjugated to a phosphorylcholine containing polymer.

- erythropoietin conjugated to a phosphorylcholine containing polymer can be used to treat human conditions such as anemia and kidney disease (e.g., chronic renal failure) and, for example, G-CSF conjugated to a phosphorylcholine containing polymer can be used to treat cancer patients receiving chemotherapy.

- conjugate of the invention that produces a therapeutic effect by repeated administration of increasing amounts of the conjugate (e.g., pharmaceutical composition containing the conjugate) to achieve a clinically desired endpoint.

- conjugate e.g., pharmaceutical composition containing the conjugate

- Proteins and peptides for use as biologically active agents as disclosed herein can be produced by any useful method including production by in vitro synthesis and by production in biological systems.

- Typical examples of in vitro synthesis methods which are well known in the art include solid-phase synthesis (“SPPS”) and solid-phase fragment condensation (“SPFC”).

- SPPS solid-phase synthesis

- SPFC solid-phase fragment condensation

- Biological systems used for the production of proteins are also well known in the art.

- Bacteria e.g., E coli and Bacillus sp.

- yeast e.g., Saccharomyces cerevisiae and Pichia pastoris

- heterologous proteins e.g., E coli and Bacillus sp.

- yeast e.g., Saccharomyces cerevisiae and Pichia pastoris

- heterologous gene expression for the production of biologically active agents for use as disclosed herein can be accomplished using animal cell lines such as mammalian cell lines (e.g., CHO cells).

- animal cell lines such as mammalian cell lines (e.g., CHO cells).

- the biologically active agents are produced in transgenic or cloned animals such as cows, sheep, goats and birds (e.g., chicken, quail, ducks and turkey), each as is understood in the art. See, for example, U.S. Pat. No. 6,781,030, issued Aug. 24, 2004, the disclosure of which is incorporated in its entirety herein by reference.

- avian derived biologically active agents such as proteins produced in domesticated birds such as chickens can be referred to as “avian derived” biologically active agents (e.g., avian derived therapeutic proteins). Production of avian derived therapeutic proteins is known in the art and is described in, for example, U.S. Pat. No. 6,730,822, issued May 4, 2004, the disclosure of which is incorporated in its entirety herein by reference.

- the biologically active agent is a protein or polypeptide

- functional groups present in the amino acids of the protein polypeptide sequence may be used to link the agent to the Z group, either directly by a covalent bond, or indirectly through a Sp 2 spacer group.

- Linkages to protein or polypeptide biologically active agents may be made to naturally occurring amino acids in their sequence or to naturally occurring amino acids that have either been added to the sequence or inserted in place of another amino acid.

- Protein or polypeptide biologically active agents may also comprise non-naturally occurring amino acids in addition to the common naturally occurring amino acids found in proteins and polypeptides.

- non-naturally occurring amino acids may be introduced to provide a functional group that can be used to link the protein or polypeptide directly to the Z group, or indirectly through a Sp 2 spacer group appended to the active agent.

- naturally occurring amino acids e.g., cysteine, may be used in this way.

- Non-naturally occurring amino acids may be introduced into proteins and peptides by a variety of means. Some of the techniques for the introduction of non-natural amino acids are discussed in U.S. Pat. No. 5,162,218, the disclosure of which is incorporated in its entirety herein by reference.

- non-naturally occurring amino acids may be introduced by chemical modification of a polypeptide or protein on the amino acid side chain or at either the amino terminus or the carboxyl terminus.

- Non-limiting examples of chemical modification of a protein or peptide might be methylation by agents such as diazomethane, or the introduction of acetylation at an amino group present in lysine's side chain or at the amino terminus of a peptide or protein.

- protein/polypeptide amino group modification to prepare a non-natural amino acid is the use of methyl 3-mercaptopropionimidate ester or 2-iminothiolane to introduce a thiol (sulfhydryl, —SH) bearing functionality linked to positions in a protein or polypeptide bearing a primary amine.

- thiol sulfhydryl, —SH

- Such groups may be employed to form a covalent linkage to the protein or polypeptide.

- bifunctional agents such as 2-iminothiolane may be considered as appending a Sp 2 group to a biologically active agent if the group introduced is used to form a covalent linkage to Z.

- non-naturally occurring amino acids may be introduced into proteins and polypeptides during chemical synthesis.

- Synthetic methods are typically utilized for preparing polypeptides having fewer than about 200 amino acids, usually having fewer than about 150 amino acids, and more usually having 100 or fewer amino acids.

- Shorter proteins or polypeptides having less than about 75 or less than about 50 amino acids can be prepared by chemical synthesis.

- Suitable synthetic polypeptide preparation methods may be based on Merrifield solid-phase synthesis methods where amino acids are sequentially added to a growing chain (Merrifield (1963) J. Am. Chem. Soc. 85:2149-2156). Automated systems for synthesizing polypeptides by such techniques are now commercially available from suppliers such as Applied Biosystems, Inc., Foster City, Calif. 94404; New Brunswick Scientific, Edison, N.J. 08818; and Pharmacia, Inc., Biotechnology Group, Piscataway, N.J. 08854.

- non-naturally occurring amino acids that can be introduced during chemical synthesis of polypeptides include, but are not limited to: D-amino acids and mixtures of D and L-forms of the 20 naturally occurring amino acids, N-formyl glycine, ornithine, norleucine, hydroxyproline, beta-alanine, hydroxyvaline, norvaline, phenylglycine, cyclohexylalanine, t-butylglycine (t-leucine, 2-amino-3,3-dimethylbutanoic acid), hydroxy-t-butylglycine, amino butyric acid, cycloleucine, 4-hydroxyproline, pyroglutamic acid (5-oxoproline), azetidine carboxylic acid, pipecolinic acid, indoline-2-carboxylic acid, tetrahydro-3-isoquinoline carboxylic acid, 2,4-diaminobutyricacid, 2,6-dia

- non-naturally occurring amino acids may be introduced through biological synthesis in vivo or in vitro by insertion of a non-sense codon (e.g., an amber or ocher codon) in a DNA sequence (e.g., the gene) encoding the polypeptide at the codon corresponding to the position where the non-natural amino acid is to be inserted.

- a non-sense codon e.g., an amber or ocher codon

- a DNA sequence e.g., the gene

- the altered sequence is subsequently transcribed and translated, in vivo or in vitro in a system which provides a suppressor tRNA, directed against the nonsense codon that has been chemically or enzymatically acylated with the desired non-naturally occurring amino acid.

- the synthetic amino acid will be inserted at the location corresponding to the nonsense codon.

- recombinant preparation techniques of this type are usually preferred.

- amino acids that can be introduced in this fashion are: formyl glycine, fluoroalanine, 2-Amino-3-mercapto-3-methylbutanoic acid, homocysteine, homoarginine and the like.

- non-naturally occurring amino acids have a functionality that is susceptible to selective modification, they are particularly useful for forming a covalent linkage to the protein or polypeptide.

- Circumstances where a functionality is susceptible to selective modification include those where the functionality is unique or where other functionalities that might react under the conditions of interest are hindered either stereochemically or otherwise.

- the biologically active agents may also be selected from specifically identified drug or therapeutic agents, including but not limited to: tacrine, memantine, rivastigmine, galantamine, donepezil, levetiracetam, repaglinide, atorvastatin, alefacept, tadalafil, vardenafil, sildenafil, fosamprenavir, oseltamivir, valacyclovir and valganciclovir, abarelix, adefovir, alfuzosin, alosetron, amifostine, amiodarone, aminocaproic acid, aminohippurate sodium, aminoglutethimide, aminolevulinic acid, aminosalicylic acid, amlodipine, amsacrine, anagrelide, anastrozole, aprepitant, aripiprazole, asparaginase, atazanavir, atomoxetine, anthracyclines, bex

- Biologically active agents may also be selected from the group consisting of aminohippurate sodium, amphotericin B, doxorubicin, aminocaproic acid, aminolevulinic acid, aminosalicylic acid, metaraminol bitartrate, pamidronate disodium, daunorubicin, levothyroxine sodium, lisinopril, cilastatin sodium, mexiletine, cephalexin, deferoxamine, and amifostine in another embodiment.

- the present invention includes and provides for pharmaceutical compositions comprising one or more compounds of the invention and one or more pharmaceutically acceptable excipients.

- the compounds of the invention may be present as a pharmaceutically acceptable salt, prodrug, metabolite, analog or derivative thereof, in the pharmaceutical compositions of the invention.

- pharmaceutically acceptable excipient or “pharmaceutically acceptable carrier” is intended to include any and all solvents, dispersion media, coatings, antibacterial and antifungal agents, isotonic and absorption delaying agents, and the like, compatible with pharmaceutical administration.

- Pharmaceutically acceptable carriers for use in formulating compounds of formula (Ia) through (Vb) include, but are not limited to: solid carriers such as lactose, terra alba, sucrose, talc, gelatin, agar, pectin, acacia, magnesium stearate, stearic acid and the like; and liquid carriers such as syrups, saline, phosphate buffered saline, water and the like.

- Carriers may include any time-delay material known in the art, such as glyceryl monostearate or glyceryl distearate, alone or with a wax, ethylcellulose, hydroxypropylmethylcellulose, methylmethacrylate or the like.

- compositions according to this invention may also be included in a pharmaceutical composition according to this invention.

- the use of such media and agents for pharmaceutically active substances is well known in the art. Except insofar as any conventional media or agent is incompatible with the active compound, use thereof in the compositions of the invention is contemplated. Supplementary active compounds can also be incorporated into the compositions of the present invention.

- the pharmaceutical preparations encompass all types of formulations.

- they are parenteral (including subcutaneous, intramuscular, intravenous, intradermal, intraperitoneal, intrathecal, intraventricular, intracranial, intraspinal, intracapsular, and intraosseous) formulations suited for injection or infusion (e.g., powders or concentrated solutions that can be reconstituted or diluted as well as suspensions and solutions).

- parenteral including subcutaneous, intramuscular, intravenous, intradermal, intraperitoneal, intrathecal, intraventricular, intracranial, intraspinal, intracapsular, and intraosseous formulations suited for injection or infusion (e.g., powders or concentrated solutions that can be reconstituted or diluted as well as suspensions and solutions).

- any suitable liquid media may be employed.